Krew Instrument, based in India, is a reputable manufacturer of static pass boxes. These boxes are commonly used in the pharmaceutical industry for transferring materials while maintaining the cleanroom classification between two areas. The static pass box serves as a barrier between two different areas and prevents air from flowing between them during material transfer. The static pass enclosure typically consists of a simple box placed between the two areas. This type of pass box is also referred to as a passive cleanroom passbox and helps to keep pollutants out of the sterile region. In summary, the static pass box is designed to hinder the flow of air between two areas during material transfer and is a passive

- It has two doors at its extreme.

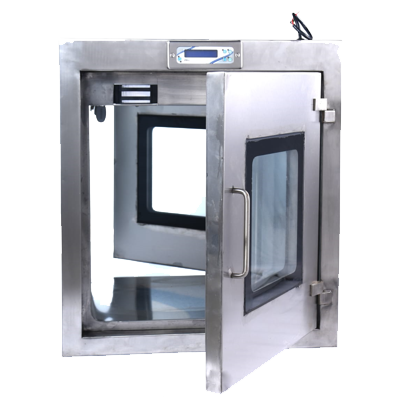

- The doors are provided with a glass window so that the material kept for transfer can be seen.

- One door opens in the cleanroom and the other door opens in the other room.

- The doors are electrically interlocked type, hence only one door can be opened at a time.

- It prevents the direct flow of air from the cleanroom to the other room and vice- versa.

- It eliminates the opening of the cleanroom door for material transfer.

- It helps in achieving the objective of material transfer without compromising the cleanliness level of the cleanroom.

Key Features

- Design acc. to GMP-Guideline easy to clean and to disinfect

- Doubled Skin Cabinet with Doors and Toughed Glass

- Cabinet Fabricated in SS 304/316 Static Pass Box

- SS 304 Hinges and Door Handle

- Electro Magnetic Interlocking System

- Pre-Installed White and UV Germicidal Light

- Feather Touch controller for Door/Light/Hour Meter for UV

- Sound Level Minimum 65db On Scale

- Power Supply Single Phase 220V 50 Hz

Special Features

- Easy to clean

- Easy to integrate

- Advanced air tightness

- Interlocking

- Sturdy Built

- UV light

Optional Features

- Customizable sizing to fit specific laboratory needs.

- Interlocking doors to prevent cross-contamination between the two compartments.

- Stainless steel construction for easy cleaning and durability.

- UV-C light for sterilization of the pass box interior.

- HEPA filtration to remove airborne particles and bacteria.

- Seamless design for a smooth and easy-to-clean surface.

- Magnetic or mechanical interlock system for added security and safety.

- Smooth surface finish for easy cleaning and disinfection.

- Adjustable shelves for versatile storage options.

- Optional air curtains for added protection against cross-contamination.

Functioning

- It has two doors at its extreme.

- The doors are provided with a glass window so that the material kept for transfer can be seen.

- One door opens in the cleanroom and the other door opens in the other room.

- The doors are electrically interlocked type, hence only one door can be opened at a time.

- It prevents the direct flow of air from the cleanroom to the other room and vice- versa.

- It eliminates the opening of the cleanroom door for material transfer.

- It helps in achieving the objective of material.

Krew Instrument, based in India, is a reputable manufacturer of static pass boxes. These boxes are commonly used in the pharmaceutical industry for transferring materials while maintaining the cleanroom classification between two areas. The static pass box serves as a barrier between two different areas and prevents air from flowing between them during material transfer. The static pass enclosure typically consists of a simple box placed between the two areas. This type of pass box is also referred to as a passive cleanroom passbox and helps to keep pollutants out of the sterile region. In summary, the static pass box is designed to hinder the flow of air between two areas during material transfer and is a passive means of preventing contaminants from entering the sterile area.

- 🛡️ Robust Stainless Steel Construction.

- 🧼 Smooth, Crevice-Free Finish.

- ⚙️ Customizable to Your Process.

- 📜 GMP & Pharma-Ready Compliance.

- 🔍 Clear Visibility Panels.

- 🧩 Easy Installation & Low Maintenance.

- 🌍 Trusted Indian Manufacturer with Global Reach.

- 100% customer support and assistance.

- Pharmaceutical industry

- Chemical research laboratories

- Electronic industry

- Food processing industry

- Semiconductor production